3.10.2021

Thriving: A Year of Resiliency

By Megan Padilla; Photos by Chad Baumer

Early March, 2020

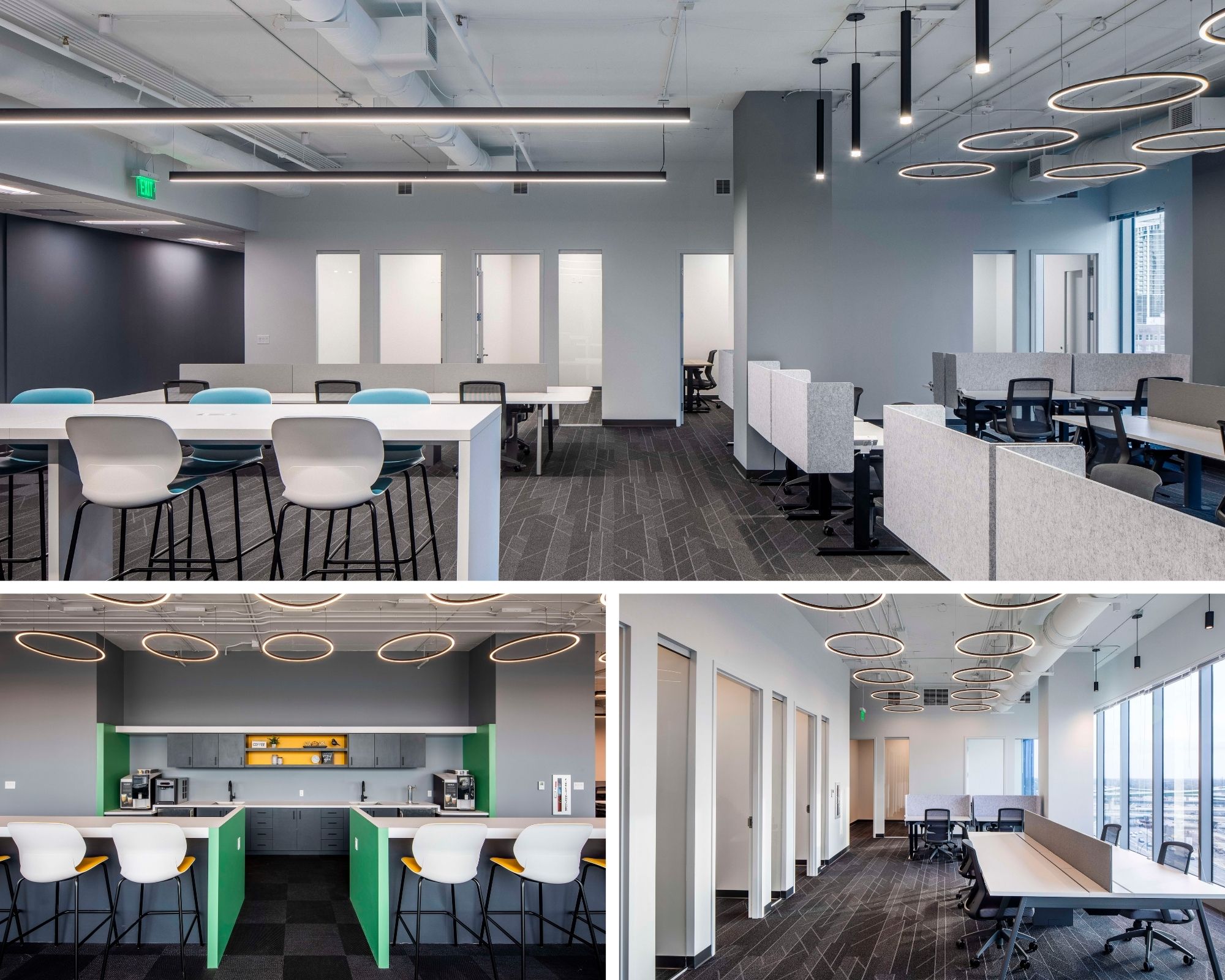

Sparks fly as Interstruct crews plow through construction projects in Orlando and Tampa. Among them: a fast-track 50,000sf interior buildout for Orlando Health, repurposing a 150,000sf Target center into a higher education campus, and completing three full floors for three tenants in the brand-new SunTrust Plaza in downtown Orlando.

And then the world shut down. No one had a play book for a pandemic.

Yet, Interstruct’s clients expected one. “Clients put the onus on us to operate safely and professionally,” says CEO Ryan Young. “It wasn’t `Let me help you.’ It was `What are you doing?’”

The challenges played to Interstruct’s wheelhouse: taking a complex problem and figuring it out. Rich Monroe — Young’s partner, with whom he founded Interstruct in 2001 — did a ton of research and wrote the company’s continuity plan.

“We responded extremely well to our client base about how we would manage our job sites safely,” says Young. “To me, that really showed our flexibility and construction intelligence. How do we make all of this stuff work?”

Despite absorbing COVID-related expenses, Interstruct posted a stellar year, not only hitting all the construction milestones for their clients, but also developing two projects of their own. In 2020, Interstruct acquired urban properties in Parramore, Orlando and South Tampa, expanding its Architect-as-Developer portfolio with adaptive reuse projects to provide flagship offices for the company and space for retail tenants.

Interstruct didn’t just survive during the pandemic, the company thrived. So, how’d they do it?

Keeping job sites open

For starters, “We didn’t have to have the battle that we weren’t considered essential workers,” says Young. “That gave us a lot of latitude to figure out how to operate safely on the job site.”

“We had our backs against the wall,” says Matt Coticchio, who helms the 10-year-old Tampa office. “Clients still wanted deadlines met and budgets held. In the beginning, we couldn’t be too safe, and we didn’t want to bring up money, so we just sucked it up.”

Among the protocols immediately put into place on job sites: daily temperature checks, a detailed logbook to use for contact tracing if necessary, a limit to the number of people on site, additional shifts to spread out workers, PPE provided by the company, hand-washing stations MacGyvered from a fish-cleaning table spotted at a sporting-goods store, remote meetings instead of in-person, and fumigation deep-cleanings as needed.

Signage and reinforcement of job site health and safety rules by field superintendents was reinforced through regular communication with the executive team. Further, the lines of communication were held open to ensure workers reported illness or potential exposures without fear of income loss.

“Rich, Ryan and I were betting on our employees,” says Coticchio. “While others were cutting people, we doubled down and invested in them. We wanted to keep everyone working and in the know, weekly, about how things were progressing as a company.”

Young recalls those early weeks and months of the pandemic. “Those of us who could work remotely did. But much of our team as well as our subcontractors were in harms’ way. It was scary. No one knew who would get sick, how bad it would be or what would happen,” he says. “I lost a lot of sleep.”

Interstruct absorbed all the expenses, though they are now starting to build them in as line items on proposals. “Owners like that we are taking these precautions,” says Coticchio, who foresees many of these items remaining in place for the foreseeable future, “and may be a standard moving forward.”

The company’s closest call with a shutdown was on a large job site where two electricians became sick and the rumor mill reached the city, leading to inspectors refusing to come out to the site.

Young explains that they were able to immediately provide full documentation to the city: of the COVID-19 test results of the electricians, an action plan for removing other workers who had been in proximity (thanks to the daily logbook intended to serve this purpose), and the receipt for a deep cleaning of the job site. “We were clearly able to articulate our response to what happened,” he says. “Within two hours of the Chief Inspector reviewing all the documentation, we were approved” to continue working.

All of this was within a 24-hour timeframe from the initial email which raised the alarm. “If we hadn’t been paying attention, this could have gone south really fast. We had all the information to deescalate the problem,” says Young, adding, “All of this happened as a team.”

Communication is Key

Rich Monroe gets to the heart of the tool responsible for Interstruct’s strong 2020 finish. “We sell ourselves as a general contractor that is good at communicating with each other and with clients and subcontractors. Now, we’ve become experts at dealing with people remotely,” he says, including project managers, field superintendents and subcontractors, clients and owner representatives, inspectors and other municipal officials.

“From a technology standpoint,” says Coticchio, “we were prepared before the pandemic to go remotely and have gotten better with the tech aspects. We feel we’re even better now at serving our clients.”

Another silver lining has been a reboot of the permitting and inspection process. “Inspectors are using technology in ways they wouldn’t have considered before,” says Monroe. “Now, they allow us to share pictures of a particular issue and will sign off on the inspection. They see it is working.”

Young adds, “This works because of the relationship and trust we’ve built with the inspectors, looped in with technology, ” says Young, who comments that the company works even more closely with inspectors than ever before.

“COVID has deepened our relationships with most people,” says Young. “Even on our own staff. COVID has made us overly involved in things. Rich and I have spent more time with our fingers on the pulse every second of everyday. We are meeting with our own folks more often and are more connected to our staff.”

For instance, a weekly project meeting is baked into the schedule where business development and bidding are regularly discussed. “Now project managers know what everyone else is working on,” says Young.

Monroe’s been leading a standing call with superintendents to be informed of what’s going on in the field. “These calls help us all connect to our supers, and for them to connect with each other.”

Adds Young, “Now, our guys and gals actually hear what’s going on with each other. Allowing them to interact in ways they never would have before. We’re going to keep doing this, COVID or not. There’s a high touch point right now of knowing what is actually going on with our jobs.”

The key to Interstruct’s Pandemic Success

Figuring out complex issues is how Young and Monroe operate their business and projects.

“We’re good at problem solving,” says Young. “We may not know the answer, but we’ll research it and talk about it, internalize it and make a plan for the best course of action. Our COVID response was an example of applying that type of methodology.

The executive team also recognized they were used to dealing with a parallel set of issues. “As an Interior GC, we are more focused on finishes and the details of dealing with everything around them,” says Monroe, citing examples such as smells, noise and dust. “We have to think about how everything effects nearby tenants; the lawyer in the next office or the doctor seeing patients.”

“The more complex, throw it at us and we’ll figure it out,” says Young. “That’s how a small business moves forward.”

Adds Coticchio, “Our core team really came together. To have a stellar year like we did, in the middle of a pandemic, is unbelievable. It’s a testimony to our teamwork and wherewithal.”