2.26.2022

Interstruct’s Solutions to Today’s Construction Challenges

Has anyone had a conversation about construction lately that didn’t include labor shortages and supply chain disruption? Every potential client asks us how we are handling these issues. We have answers.

We’re not just shrugging our shoulders and accepting months-long delays that add massive costs to our clients’ projects. It is our job to set expectations for the client and because of our experience, we can. We’ve been refining our in-house design-build process for years so we can build better, remove the pain points for our clients, and have the power to find solutions that keep projects on track.

We are working hard to think outside the box. That is the only way we will continue to be successful.

Matt Coticchio, President, Interstruct

Of course, we never imagined that our “thinking outside the box” methods were training our team for this extraordinary moment that demands being nimble, leaning into relationships nurtured beyond the job site, and finding solutions in unexpected places. Despite all the challenges in today’s construction landscape, we are still pumping out award-winning healthcare, corporate interiors, hospitality and ground-up projects. Here’s how.

The biggest “pain points” we’re seeing in Central and West Florida

The workforce is tough, and access to supplies–especially raw materials and specialty materials–is difficult. Lead times for essential building materials are now six months to a year. Add rising costs to the equation and the forecast appears rather dismal.

According to a recent article, A Rebound for Design and Construction, in AIA Architecture, “Construction costs overall rose about 20% last year, with those for some products (e.g., steel and oil-based products) rising more than 50%.” cites author Kermit Baker, Hon. AIA.

Those are painful numbers for building schedules and budgets that win bids and keep clients happy. While we can’t control the cost of materials, we have discovered many workarounds to keep projects on schedule and our clients satisfied.

A design + build firm that finds solutions to supply chain challenges

Three areas we’ve significantly shored up are client trust, strong vendor relationships, and creative problem-solving to keep schedules intact. Our super-power is fully on display when we get to combine all three. “Because we control this process better than others, and do this stuff in house,” says Interstruct President Matt Coticchio, “we are providing a better service.”

We take the additional time to cultivate the relationships with our vendors,” says Interstruct CEO Ryan Young, “which means we are addressing issues before they come up.”

Three areas we’ve significantly shored up are client trust, strong vendor relationships, and creative problem-solving to keep schedules intact.

Ryan Young, CEO, Interstruct

“Because we are the designers and the general contractor, we can get out ahead of this stuff early,” says Coticchio. “We can spec certain products and systems that we can find,” says Coticchio. We’re now talking about doing hollow core systems in place of steel joist systems.

Creative problem-solving means looking at geographic locations and shipping alternatives, too. A Florida manufacturer is making a certain type of hollow core slabs, “Which helps with lead times,” says Young. “We can even go down and pick them up. With trucker shortages and shipping delays, we are looking to source materials in Florida that we can go and get ourselves.”

A client recently told us, “We’re ok to change gears on certain products, but we need you to take the lead.”

Plan B requires us to tap our significant local resources to fabricate custom pieces to cut a 20-week lead time down to 9. Or turn to a local supplier who bought the machinery and found the resources to build doors. “We’re being told 12 weeks through traditional commercial construction supply channels, says Young. “We can’t wait 12 weeks for a door. Our projects are built in 12 weeks!”

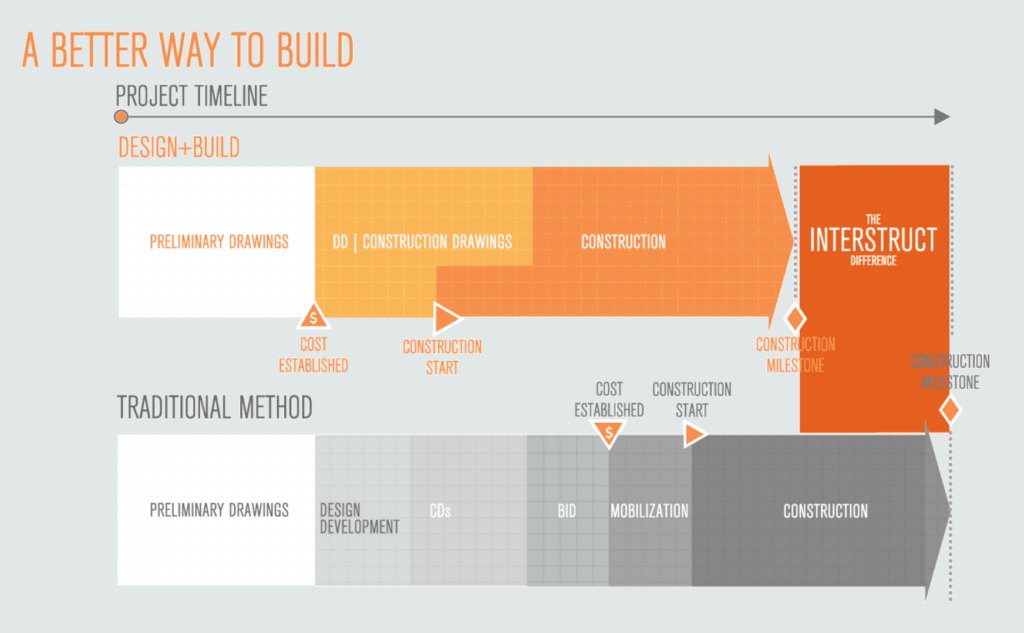

Why our Design + Build model works

“When clients ask a question, we have an answer for how we’re dealing with this situation,” says Young. “I see their face light up.”

“All of what we’re doing is moving us towards our design-build model which is 100% more efficient for our clients,” says Young. “We’re delivering on time because we’re working through these channels behind the scenes.” This behind-the-scenes effort adds value.

“As we continue our architect-developer mentality, I tell clients `You are saving time because we’re steering your design towards your budget goals,’” says Coticchio. “We are working hard to think outside the box. That’s the only way we are going to continue being successful.”

As a small scale developer for our own projects we know what it’s like to make decisions based on the best interest of the project. We will apply this knowledge gained though our Architect-Developer model and treat your project as though it were our own.

It’s not all doom and gloom. “We are thoughtful about the process, do everything in house, and are prepared,” says Young. “Come to us with your next project.”

Some highlights from Interstruct’s portfolio